Sculpting a Styrene Wooden Cart

Hi Everyone!

Today is time for some wooden architecture!

I’ve seen many wooden works in 28 mm or smaller, but most of them where

too fat or exagerrated to match with the non-fantasy stuff. While you

can find load of metal accessories around the Net, it is quite hard to

find anything made of wood or cloth or similar.

I had quite a lot of experience working with balsa wood, but for some reasons for the thinner parts and the most detailed i prefere using plasticard (styrene) sheets and strips, using a method that i learned from the article from Emmanuel Nouaillier, and then i adapted for my needs.

Mainly, in this article i’ll show you how to work with styrene, what technique to use and what tools are better, of course in my experience.

I’m pretty young, and i expect to improve even in this field, so probably in a couple of years i will find this partially wrong.

Probably i’m gonna make a specific article about the styrene techniques, so i won’t be too long on the technical part here.

I’m pretty young, and i expect to improve even in this field, so probably in a couple of years i will find this partially wrong.

Probably i’m gonna make a specific article about the styrene techniques, so i won’t be too long on the technical part here.

Now, let’s start with the tutorial.

Part 1: The Body

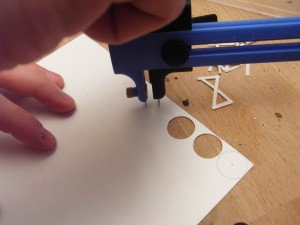

The starting material of the main parts of

the cart is of course the Plasticard. I choose it instead of balsa for

his thickness and his level of detail: since this is not a siege engine, nor a big wooden structure, the planks are usually thinner and shorter, put together with small nail.

I started cutting the shapes of the various

parts. I didn’t use any sort of blueprints, but i had quite a good

image in my mind about the shape of the finished product.

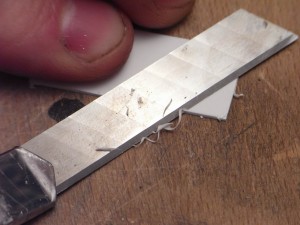

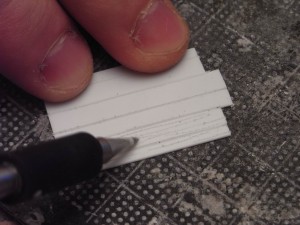

Note: when you cut the styrene the two edges will be deformed, and you have to remove

the part in excess.Pulling the cutter’s blade on the surface will grant

you to not remove too much from the sheet. If you see a nice and

regular spiral coming away from the piece, then you’re doing it right!

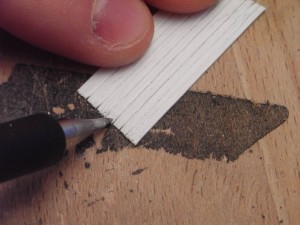

After that, I used my scribler to carve the plank lines

on the plastic. Make the line many times, until it is quite deep in the

plastic, probably you’ll have to be able to recognize it on the other

side!

After this, just use the same scribbler to

carve lightly some wooden grain. Nothing too accurate, just lines and

maybe nodes, to suggest to the metal brush where to scratch. As i said, a good metal brush is perfect to enhance the grain and obtain quite a good result (and it works also with balsa!). I use an iron one, but the brass one is good as well, if enough thick.

Once passed several times the brush, the

wooden grain will come out. Now, with the metal tip, make the edges of

the planks more irregular.

Of course, if you are planning to make something more modern and less homemade you can avoid this. But still be careful about that! If the cut is too clean then it will become unrealistic!

Of course, if you are planning to make something more modern and less homemade you can avoid this. But still be careful about that! If the cut is too clean then it will become unrealistic!

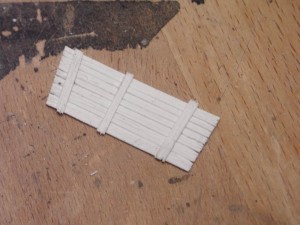

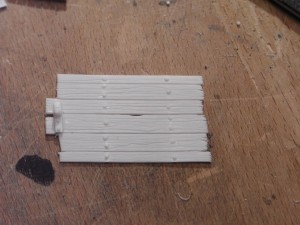

Now, i used some 0,25mm plasticard for the trasversal planks. Same treatment as before.

For the needles i used a .025″ rods from Evergreen,

sliced in small pieces, less than 0,2 mm! If the slices are a bit

irregular it’s even better, but be careful to make orthogonal cuts,

unless you like really crooked nails!

Since gluing them with a drop of glue for each one is quite absurd (the halo left is really bad) i preferred to dip them into the drop, and then put them on the proper place. In this way you will use only the needed glue, saving glue and making a more accurate work!

Since gluing them with a drop of glue for each one is quite absurd (the halo left is really bad) i preferred to dip them into the drop, and then put them on the proper place. In this way you will use only the needed glue, saving glue and making a more accurate work!

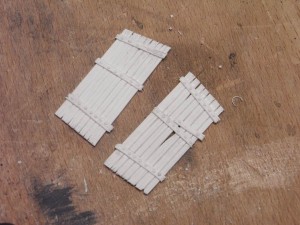

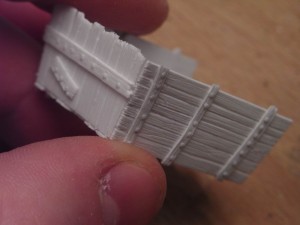

Once glued, the pins will look like this:

Then i started the base of the cart: same

technique, but i meant to represent whider planks. As before, i started

scribbling the planks border heavily and then the wood grain, trying to draw nodes and simple lines all around.

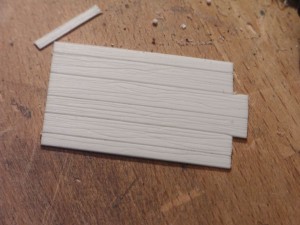

After the metal brush work, it looked like this:

Note:

before making the nails, i always use a metal spike to carve some holes

where the pins will be placed: this way you will represent the

deformation of the wood for the nail pressure, and it will be easy to

place them in the small crater.

After a whise sanding, and with a small detail added, it was finished.

Note: as you noticed, the end of the planks this time have to be very irregular. So i cutted them differently, and after a small work i metal-brushed them really heavily.

Note: as you noticed, the end of the planks this time have to be very irregular. So i cutted them differently, and after a small work i metal-brushed them really heavily.

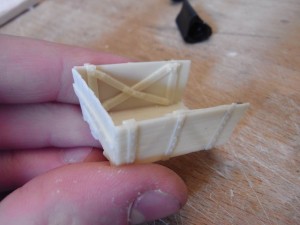

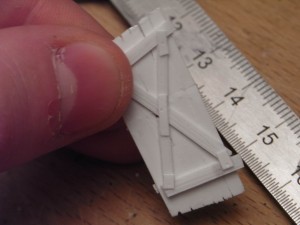

With few temporary drops of glue, i merged the pieces together to get an idea of the final look:

As you see, the base plank fits perfectly with the others.

I was quite satisfied, but there was something really missing: in the insides, the faces were too flat.

Sculpting the insides was impossible, since i prefere working with

monovalve moulds. So i decided to add something different. Some

reinforcement pieces, which can be painted easily, hiding the flatness

of the surface.

And that’s the overall view:

Part 2: The Structure

Then i started working on the below part:

the structure of the wheels and the… the parts that is joint with the

animal. I used styrene parts and a bit of cardboard for the thickness…

but every surface visible is made of styrene, and texturized!

For the metal parts i used some lead strips i cutted from a sheet. I use it (even if it is quite toxic) because it lovely fits in any corner, just like the real metal (actually it is metal)

For the metal parts i used some lead strips i cutted from a sheet. I use it (even if it is quite toxic) because it lovely fits in any corner, just like the real metal (actually it is metal)

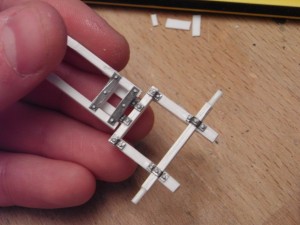

The mechanism is made in two parts, which i

glued together for the picture. For the nails I used the same method as

above, and the result is quite great, imho!

Part 3: The Wheels

I fought long against myself for the wheel’s type: Full wooden ones or spoked ones. At the end i choosed the wooden one: more versatile, it can be used from ancient periods to wwii with no problems, and it is much easier to sculpt, too.I wanted something more thick than a 0,5mm sheet, so i glued two of them together. For the round shape i used a tool i brought in Japan last time i’ve been there: something really useful!

After the usual treatment, the wheels looked like this:

But i wanted to make them a bit more realistic, so i added a metal cover around the wooden part. Another lead strips was the best choice.

Part 4: The Moulding

Then finally i made the mould shape. As always i used some cheap foamcore, because it is quite flat and regular, and also easy to cut!

The silicon took several days to vulcanize, since i used the wrong amount of catalyzator. but finally i managed to have a couple of resin casts (much more if i want! ^^)

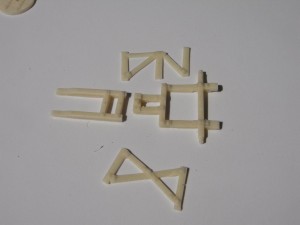

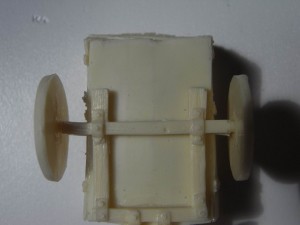

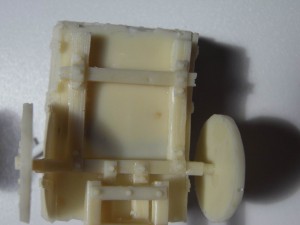

Here is the sctructure:

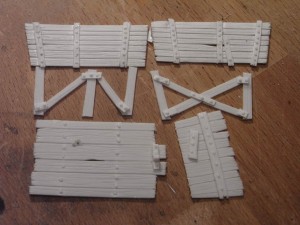

And here the flat parts:

Starting from the core, i had some problems

assembling it. The pieces aren’t perfectly sized, so i needed to do

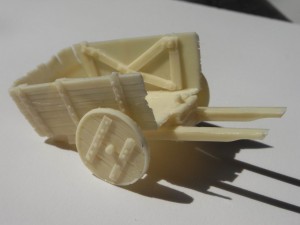

some adjustement with the cutter. Here is the Result:

The main problem is in the wheels: the wheels were too much at the end of the cart. So the cart wasn’t balanced. Nothing too difficult, i had to cut the wheels:

At the end, that’s the final piece!FROM THISTO THIS

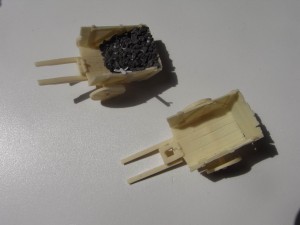

I added to the first cart a load of coal and a shovel (not easy to see in the photo)… the two carts together are shown as below:

Conclusions:

Working with plasticard (styrene) is quite enjoyable, and the wooden grain is much more realistic than the balsa one. Actually, the balsa method (which i will show soon or later in a proper article) is much faster, and with some sizes of food is as good as this one. (If you like, here is another piece i made some time ago in the same way!)

For historical scultping i prefere the styrene way, but for the fantasy it is not enough… exalted!

Anyway, with the same technique is possible to make a lot of different effects, from the bended wood to the metal, and even rocks or paper!

Hope you like,

Wow, amazing work! I applaud both your patience and creativity. Well done!

ReplyDelete